In the dynamic world of logistics, efficiency is not just an objective; it’s the lifeblood that keeps the industry thriving. Businesses are under constant pressure to elevate their game in speed, accuracy, and cost-effectiveness. Innovation is not just welcomed; it’s demanded. This is where the modular dolly, a seemingly unassuming innovation, becomes a linchpin in the grand scheme of logistical operations.

At TriWich, we’ve recognized that the seamless movement of goods is not just a part of commerce; it is commerce. That’s why we’ve poured our passion and expertise into developing modular dolly systems that transcend the role of mere tools to become catalysts for transformation. These are not your run-of-the-mill dollies; they are the offspring of rigorous engineering, born to confront and conquer the intricate challenges of today’s logistics.

The Logistics Landscape: Challenges and Opportunities

The logistics sector is fraught with challenges ranging from the optimization of space to the relentless quest for speed and the imperative of cost reduction. Yet, within these challenges lie vast opportunities for those willing to innovate. Modular dollies represent such an innovation, turning potential obstacles into stepping stones towards greater efficiency.

Space in warehouses is precious, and traditional handling methods often fall short in optimizing this space. Modular dollies, with their compact design and maneuverability, allow for tighter turns and more efficient use of warehouse real estate. Speed is of the essence in logistics, and the agility of modular dollies translates into faster movement of goods. Cost, the ever-present concern, is addressed through the durability and versatility of these dollies, ensuring a longer life span and adaptability to various tasks, reducing the need for multiple handling systems.

Understanding Modular Dollies

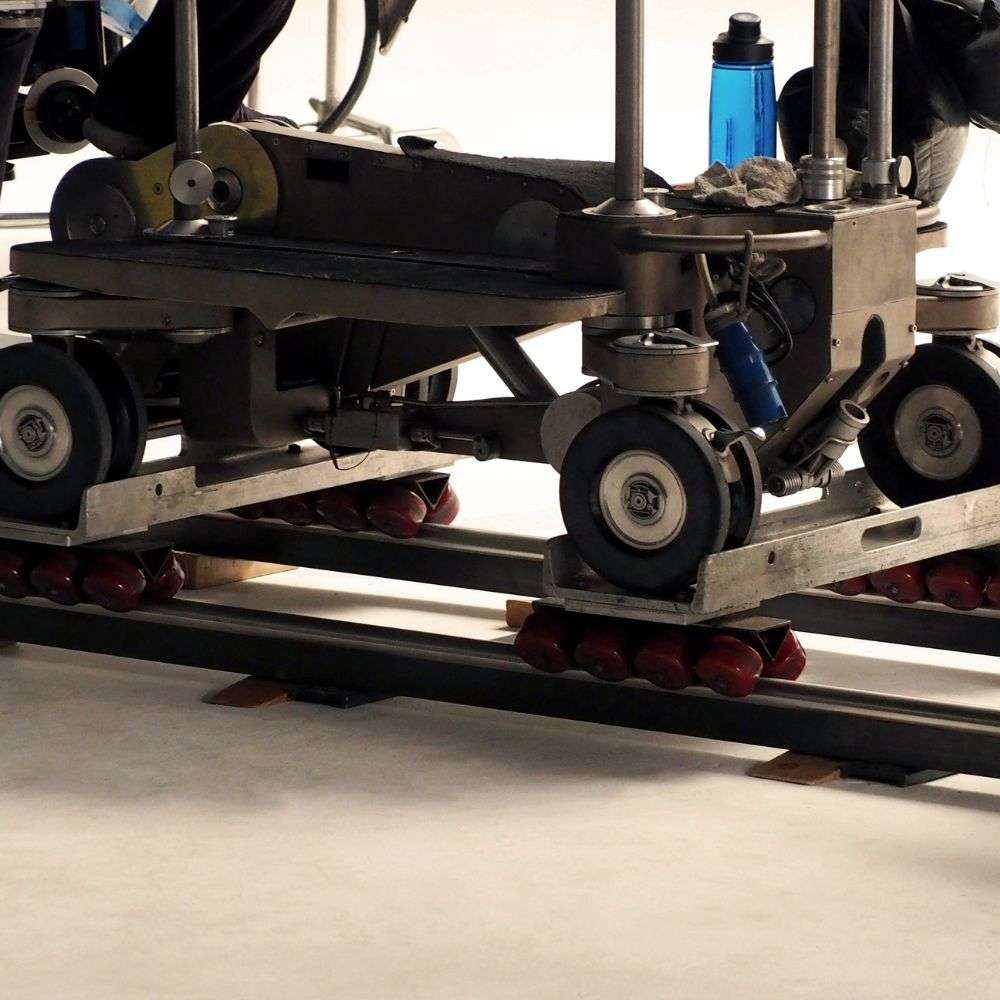

What exactly are modular dollies? They are a system of interlocking and interchangeable units that provide a customizable platform for moving goods. Unlike traditional fixed dollies, modular dollies can be reconfigured to suit different shapes and sizes of cargo, making them a versatile asset in any logistics toolkit.

TriWich’s modular dollies are a testament to this versatility. Designed with the end-user in mind, they feature adjustable components that can be swiftly reassembled to accommodate a diverse range of cargo, from standard pallets to irregularly shaped machinery. This adaptability not only enhances functionality but also eliminates the need for multiple types of equipment, streamlining the logistics process.

The Efficiency Edge: Benefits of Modular Dollies in Logistics

The benefits of integrating modular dollies into logistics are manifold. Firstly, their unparalleled maneuverability allows for the navigation of tight spaces with ease, reducing the time taken to load and unload goods. Secondly, the scalability of modular dollies means they can be expanded or reduced in size to meet the demands of the cargo, ensuring optimal load stability and safety.

TriWich’s modular dollies also boast an impressive load-bearing capacity, capable of handling weights that would typically require more substantial machinery. This strength, coupled with their lightweight design, means that they can move heavy loads without the need for fuel-powered vehicles, reducing emissions and enhancing the sustainability of logistics operations.

Technological Integration: Modular Dollies in the Age of Automation

In an era where automation is king, modular dollies stand ready to integrate seamlessly into automated workflows. With features that cater to robotic systems, such as uniform docking points and electronic tagging capabilities, TriWich’s dollies are designed to be future-proof.

The potential for modular dollies in automated logistics is vast. They can serve as mobile platforms for robotic arms, transport goods between automated guided vehicles (AGVs), or act as temporary storage units within an automated sorting system. This integration streamlines processes, reduces human error, and paves the way for a more cohesive and synchronized logistics environment.

Cost-Effectiveness and ROI

The financial implications of adopting modular dollies are significant. By enhancing efficiency and reducing the need for multiple handling systems, they offer a substantial return on investment (ROI). The initial cost is quickly offset by the savings in time, labor, and maintenance.

TriWich’s commitment to quality ensures that each modular dolly is built to last, reducing the frequency of replacements and repairs. Moreover, the time saved in handling and transportation translates into faster delivery times, increased customer satisfaction, and the potential for a greater volume of business.

Case Study: TriWich’s Modular Dolly in Action

To illustrate the impact of our modular dollies, consider the case of a TriWich client in the automotive industry. Faced with the challenge of transporting heavy engine parts within their manufacturing plant, they turned to TriWich’s modular dolly system. The result was a 30% reduction in transportation time and a 20% decrease in labor costs. The modular nature of the dollies allowed for quick reconfiguration to accommodate different parts, while their robust design ensured the safe and secure transport of valuable components.

Conclusion

The logistics industry is at a crossroads, where the traditional ways of moving goods are being challenged by innovative solutions like modular dollies. TriWich stands at the forefront of this revolution, offering products that not only meet the current demands of logistics but anticipate the needs of the future.

Our modular dollies are more than just equipment; they are a promise of efficiency, a commitment to sustainability, and a testament to American ingenuity. As we continue to push the boundaries of what’s possible in logistics, we invite you to join us in this journey of innovation and excellence. With TriWich, the future of logistics is not just efficient; it’s modular.