Moving heavy containers doesn’t have to be complicated — or expensive. If you’re like most people managing container operations, you’ve probably wondered, “Is there a smarter, more affordable way to move these things?” The good news is, there is. Modular Container Mobility Solutions are changing the game, and companies like TriWich are leading the way.

Old-school methods for moving containers usually come with big costs: pricey equipment, lots of labor, regular repairs, and downtime that eats into your schedule (and your budget). Over time, these problems add up — making it clear that there has to be a better way to get the job done.

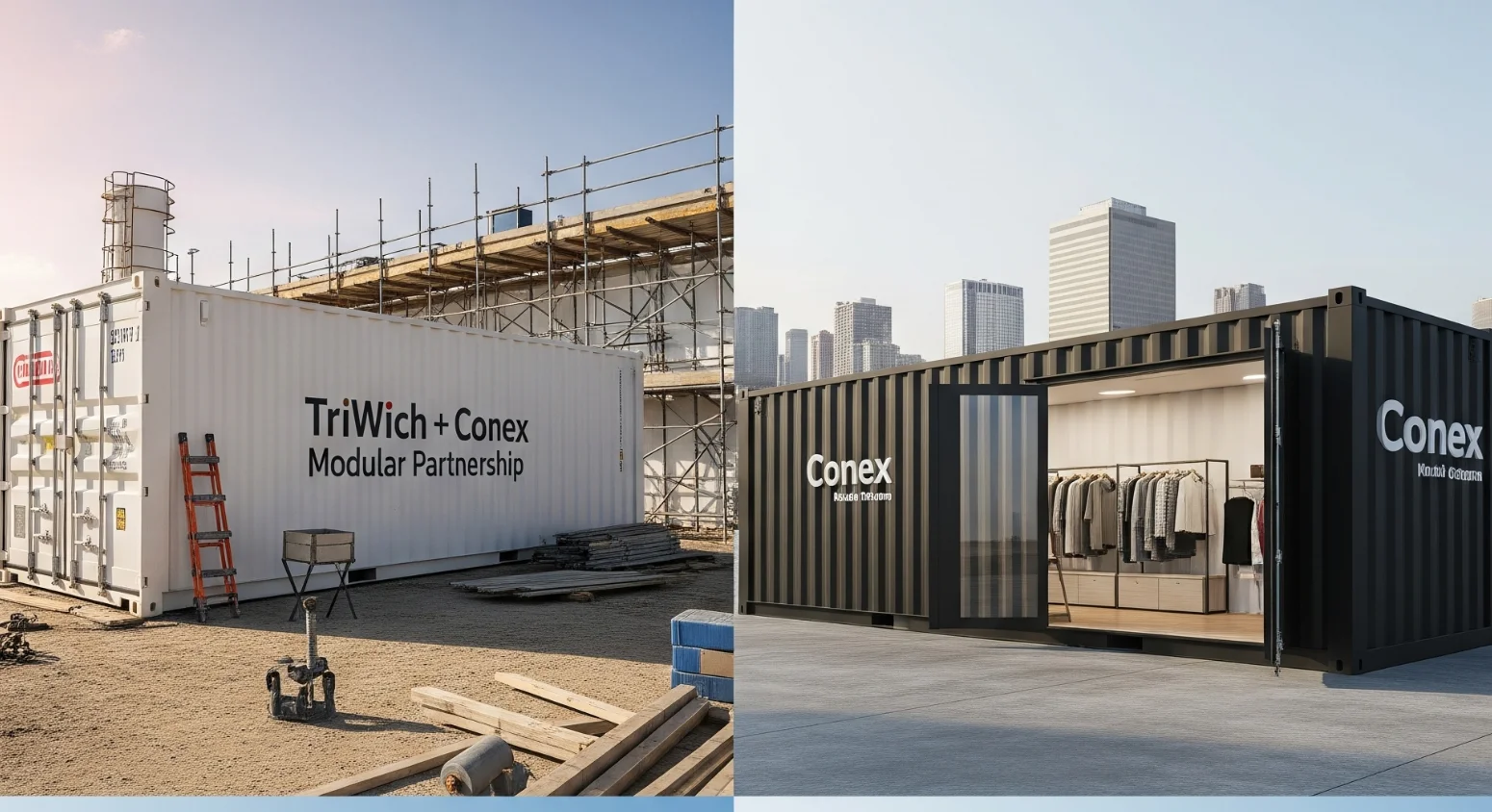

That’s where modular systems come in. They’re designed to be flexible, easy to use, and built for long-term savings. Whether you’re working in construction, warehousing, emergency response, or any industry that moves containers, switching to a modular solution can make a huge difference. And with smart options like those from TriWich, you can move faster, spend less, and work smarter.

Table of Contents

What Is a Modular Container Mobility Solution?

When you hear the phrase Modular Container Mobility Solution, you might wonder — what exactly does that mean, and why should it matter to my operation? Great questions. Let’s break it down in a way that’s clear, practical, and easy to apply to real-world container moving challenges.

Simply put, a modular container mobility solution is a flexible system designed to move containers of different sizes and types using customizable, interchangeable parts. Instead of needing a dedicated machine for every job, modular solutions like those from TriWich give you one smart setup that can handle many tasks — saving you time, money, and a lot of headaches.

Why Modularity Matters

Traditional container moving methods often require heavy-duty, single-purpose equipment that’s expensive and difficult to adapt. But with a modular system, you get:

- Flexibility to adjust the system to the container’s size, shape, and weight.

- Efficiency in moving containers quickly without waiting for special machinery.

- Cost Savings by using fewer tools to do more jobs.

Think about it like building blocks — you only add the pieces you need, when you need them. That kind of flexibility means fewer expenses and faster operations.

How Modular Systems Like TriWich Work

Companies like TriWich have designed systems that make moving containers easier and more efficient. Their solutions often include components like:

- Liftwich that safely raise heavy containers without needing cranes.

- Wheel dollies that allow containers to roll smoothly across different surfaces.

- Attachment points that can be quickly switched to handle different container sizes.

Because these pieces work together, you’re not stuck with a one-size-fits-all tool. Instead, you get a modular, scalable solution that grows with your business.

Key Benefits You Should Know

Still wondering if a modular approach makes sense for you? Here are a few quick reasons why it’s becoming the smarter choice:

- Adaptability — Move different types of containers with one system.

- Reduced Downtime — Faster setup means less waiting around.

- Lower Maintenance Costs — Modular parts are easier and cheaper to replace.

- Better Space Utilization — Compact, modular equipment takes up less storage room.

Major Cost Factors in Traditional Container Mobility

Have you ever stopped to think about all the hidden costs tied to moving containers the traditional way? If you’re using old methods, you might be spending a lot more than you realize — not just in money, but in time, energy, and lost opportunities. Let’s break down where those costs sneak in and why it might be time for a smarter solution.

1. High Labor and Equipment Expenses

Traditional container transport often demands:

- Specialized machines like cranes, forklifts, or heavy trucks.

- Trained operators who can safely manage these large pieces of equipment.

- Extra personnel for tasks like guiding moves, securing loads, or handling unexpected problems.

All of these factors add up quickly. Labor costs, in particular, are one of the biggest drains on container operations. Plus, maintaining and fueling big equipment isn’t cheap either.

2. Inflexibility Leading to Increased Operational Costs

Most traditional systems are built for a single purpose. If you suddenly need to move a container that’s a different size or located in a tighter space, you often have to:

- Rent or buy new equipment.

- Bring in specialists.

- Spend extra time reworking your plans.

This lack of flexibility leads to lost hours and blown budgets — something no operation can afford long term.

Modular Container Mobility Solutions, like those offered by TriWich, solve this problem by letting you adjust the system to fit almost any situation. It’s a smarter way to stay ready for whatever comes your way.

3. Frequent Maintenance and Equipment Downtime

Here’s something you might already know too well: traditional heavy equipment breaks down — often when you need it the most. Common issues include:

- Mechanical failures.

- Worn-out parts that are expensive and slow to replace.

- Unexpected downtime that halts entire projects.

Every minute your container sits still costs you money. But with modular solutions like wheel dollies and lift systems from TriWich, you’re working with simpler, durable tools that are easier and cheaper to maintain. That means fewer breakdowns, less downtime, and lower repair costs over time.

4. Storage and Transportation Inefficiencies

Bulky traditional equipment doesn’t just cost more to use — it costs more to store and transport. Big machines need:

- Larger storage spaces.

- Expensive trailers for moving from site to site.

- Special handling that adds complexity and costs.

Modular mobility solutions are designed to be lightweight, compact, and easy to transport. That’s a major bonus if you’re looking to cut overhead costs and keep your operations nimble.

How Modular Solutions Like TriWich Lower Costs

You might be thinking, “Modular solutions sound promising, but how exactly do they save money day-to-day?” Great question — and one that deserves a real, detailed answer. Let’s walk through the major ways systems like TriWich’s Modular Container Mobility Solutions can seriously cut your costs while boosting your efficiency.

1. Multi-Functional Designs Replace Multiple Tools

Instead of buying several different machines to move different types or sizes of containers, modular systems offer flexible tools that adapt on the fly. For example, TriWich’s Wheel Dollies and lift systems can be reconfigured easily to match whatever your project needs.

The result?

- Fewer equipment purchases.

- Less money spent on specialized machinery.

- Lower long-term investment for the same (or better) performance.

It’s like having one smart tool instead of five expensive ones.

2. Faster Container Handling Reduces Labor Costs

Speed matters. Every extra minute it takes to move a container adds to your labor bill. Traditional systems often involve long setup times, heavy lifting coordination, and complex operations. But with TriWich’s modular solutions, moving containers becomes:

- Simpler.

- Faster.

- Safer.

When you spend less time setting up and moving containers, you cut labor hours dramatically — which means significant savings over the course of every project.

3. Durable, Low-Maintenance Equipment Saves on Repairs

Heavy-duty doesn’t have to mean high-maintenance. TriWich designs their modular systems with durability in mind, using rugged materials that stand up to real-world wear and tear. Plus, if something does wear out, modular systems are easy to repair because you can:

- Replace only the broken parts.

- Avoid costly, full-equipment overhauls.

- Minimize downtime with quick fixes.

Less time in the repair shop means more time getting work done — and that’s money back in your pocket.

4. Real-World Examples of TriWich’s Cost-Effective Impact

Let’s get practical. Here’s how real businesses are seeing major returns by switching to modular solutions:

- Construction companies are reducing on-site delays by using TriWich Wheel Dollies to quickly position heavy containers exactly where they need them.

- Logistics firms are saving thousands annually by using modular container movers instead of renting expensive cranes.

- Emergency response teams are getting critical supplies delivered faster without relying on oversized, costly machinery.

When you add it up, the savings from modular systems aren’t just theoretical — they’re real, measurable, and transformative.

Choosing the Right Modular Solution for Maximum Value

With so many container mobility options out there, how do you know you’re picking the one that will truly save you time, money, and stress? Choosing the right Modular Container Mobility Solution isn’t just about buying the newest system — it’s about finding the setup that fits your specific needs today and can grow with you into the future.

Let’s walk through what to look for so you can make the smartest investment possible.

1. Key Features You Should Prioritize

Not all modular systems are created equal. Before you commit, make sure the solution you’re considering offers:

- True Modularity — Can parts be swapped, added, or upgraded easily?

- Heavy-Duty Construction — Are materials strong enough for long-term, real-world use?

- Easy Maneuverability — Does the system work well in tight spaces or uneven ground conditions?

- Low Maintenance Needs — Will it save you money in repairs and upkeep over time?

TriWich’s modular solutions hit all these marks, making them a top choice for industries that demand both performance and flexibility.

2. Scalability: Growing with Your Operational Needs

Think about where your operation will be a year from now — or five. Can your container mobility system grow with you? A good modular solution should let you:

- Start small with essential components.

- Add new modules or attachments as projects get bigger.

- Avoid replacing your whole system just because your needs change.

TriWich designs their Wheel Dollies and container movers with future growth in mind, offering the kind of scalability that protects your investment for the long haul.

3. Why TriWich Stands Out Among Modular Mobility Options

You have choices — but few companies match what TriWich brings to the table. Here’s what sets them apart:

- Proven Durability — Tested in real-world conditions to handle the toughest jobs.

- Customer-First Design — Built based on feedback from professionals who move containers every day.

- Innovative Engineering — Systems that combine strength, ease of use, and modular flexibility.

When you choose TriWich, you’re not just buying a product — you’re investing in a smarter way to move containers, save money, and future-proof your operations.

Conclusion: Move Smarter with Modular Solutions

Now that you know how much a Modular Container Mobility Solution can change your operations, it’s clear that moving containers doesn’t have to be complicated or expensive. Instead of relying on costly, single-purpose equipment, switching to a modular system could save you time, money, and effort.

Think about it:

- Are you tired of spending too much on heavy machinery and repairs?

- Do you want a solution that can handle different jobs without needing new tools every time?

- Are you looking for a way to make your business more flexible and efficient?

If you answered yes, then it’s time to explore a modular solution — and TriWich is here to help. With TriWich’s modular systems, you get:

- Strong, durable equipment that works in tough conditions.

- Simple, easy setups to move containers in tight spaces.

- Significant savings on maintenance and labor costs.

Switching to a modular system is about more than just moving containers. It’s about making your whole operation faster, more cost-effective, and ready for whatever comes next. With TriWich’s Wheel Dollies and modular movers, you’ll be ready for the future.

Are you ready to move smarter? The first step starts with finding the right solution for your needs.

FAQs

1. What is a Modular Container Mobility Solution?

A modular container mobility solution is a flexible system that lets you move containers of different sizes with easy-to-change parts. Unlike traditional systems, it’s adjustable and cost-effective, like TriWich’s tools, which can be used for many different jobs.

2. How do modular systems help with moving containers in tight spaces?

Modular systems, like TriWich’s Wheel Dollies, are designed to be small and easy to move, making it much simpler to position containers in narrow or tricky spots, where big machines just can’t fit.

3. Can TriWich’s modular systems handle heavy containers?

Yes! TriWich builds their modular systems to handle heavy loads while remaining flexible and easy to use. You’ll get the strength you need without the high costs or complicated setups.

4. Will switching to a modular system really save me money?

Yes, switching to a modular solution can save you money in many ways: by reducing the need for multiple machines, cutting down on labor costs, and lowering maintenance expenses. Over time, the savings really add up.