Running a freight yard efficiently is no small task. Between managing tight schedules, handling heavy container movements, and ensuring worker safety, small inefficiencies can quickly grow into major logistics challenges. Many yard managers face the same question: How can we move faster, safer, and smarter without massive investments?

The answer lies in modular mobility solutions — innovative systems designed to boost freight yard efficiency, optimize container handling, and adapt to changing operational needs. Unlike traditional fixed infrastructures, modular solutions offer the flexibility and scalability today’s freight yards demand.

In this blog, we’ll take a close look at where inefficiencies often hide, how modular mobility tools can significantly transform your yard’s performance, and how to select and implement the right solutions for lasting results. Whether you’re aiming to optimize your yard layout or improve container handling equipment, we’ll help you build a smarter, more agile freight yard.

Table of Contents

Identifying Inefficiencies in Freight Yards

Let’s be honest — running freight yard operations smoothly is a lot harder than it looks. You’re juggling tight schedules, heavy equipment, limited space, and a whole lot of moving parts. So when delays or slowdowns start creeping in, it’s easy to chalk them up to “just part of the job.” But the truth is, small inefficiencies can pile up fast, and before you know it, they’re dragging down your yard efficiency and creating serious logistics challenges.

Here’s where most yards start losing time (and money):

- Traffic jams inside the yard. Trucks getting stuck, blocked, or constantly rerouted? It’s killing your flow.

- Outdated, manual processes. If your team is still doing things the hard way, those minutes add up — fast.

- Broken or overbooked equipment. Nothing slows things down like waiting on a container mover that’s out of commission.

- Wasted space. If containers are stacked badly or your yard’s layout doesn’t make sense, you’re losing efficiency every single day.

- Poor communication. One missed radio call can trigger a domino effect of delays.

Sound familiar? You’re not alone. Most freight yards face a mix of these problems, but they don’t always realize how much it’s costing them.

Think about it:

- How often are your teams waiting around instead of working?

- Where are the bottlenecks happening — and are they getting worse?

- Are you really getting the most out of the space and equipment you already have?

If you’re nodding your head right now, that’s actually a good thing — because recognizing the issues is step one. And the good news? These problems aren’t as complicated to fix as they might seem.

In the next section, we’re diving into how modular mobility solutions can turn all these headaches into a streamlined, high-efficiency freight yard. Let’s keep going.

How Modular Mobility Solutions Transform Freight Yards

If you’re serious about freight yard optimization, it’s time to take a hard look at the tools and systems you’re using. Because here’s the truth: the old way of doing things — relying on fixed infrastructure and rigid equipment — just doesn’t cut it anymore.

This is where modular mobility solutions come in and completely change the game.

Instead of forcing your operations to fit outdated setups, modular systems adapt to you. They’re flexible, scalable, and designed to keep your freight yard running smoothly, no matter how much your workload shifts. Let’s break down the key ways modular mobility transforms your yard:

1. Faster, Smarter Container Handling

With modern container handling equipment that’s modular by design, you can move containers quicker, safer, and with fewer resources.

- No more bottlenecks from overworked cranes.

- No more waiting for specialized movers.

- No more expensive downtime.

Instead, modular tools give you the freedom to handle containers when and where you need them — without the heavy infrastructure costs.

2. Maximizing Your Yard’s Space

One major advantage of modular mobility solutions is how well they help you use every inch of available space.

- Reconfigurable systems mean you can easily adjust layouts based on the size, type, and flow of cargo.

- You’ll reduce dead zones and eliminate wasted space, making your yard not just busier — but smarter.

It’s freight yard optimization at its best: less clutter, more flow, better results.

3. Boosting Safety Without Slowing Down

Heavy-duty container movements will always come with risk. But modular equipment is engineered with safety and ease of use in mind.

- Lower manual handling requirements mean fewer injuries.

- Streamlined traffic paths mean fewer accidents.

- Smart designs minimize operator strain, helping you protect your team and maintain high productivity.

4. Future-Proofing Your Operations

The shipping and logistics world isn’t standing still — and neither should your freight yard. Modular mobility lets you scale up or reconfigure as your needs change, without needing massive new investments.

Whether you’re adding more capacity, switching to different container types, or adjusting for seasonal peaks, modular systems keep you agile and ready.

Selecting the Best Modular Mobility Tools for Your Needs

Now that you understand how modular mobility solutions can completely transform your freight yard, the next crucial step is choosing the right tools for your specific needs. After all, not all freight yards are the same, and not every solution will work in every environment.

So, how do you make sure you’re selecting the best modular equipment for your yard’s unique layout and workflow?

Let’s break it down.

1. Assess Your Yard Layout

Start with the basics: understanding your space.

- Is your yard small and cramped, or do you have plenty of room to maneuver?

- Are you dealing with high traffic volume, or do containers tend to sit for longer periods?

- Do you have a mix of container types, or do you specialize in one?

If your yard is tight on space, you’ll need modular mobility solutions that maximize your available square footage. Tools that are compact, flexible, and easily adaptable to different container sizes will give you the freedom to work in ways traditional equipment can’t.

2. Look for Scalability

Your yard’s needs will evolve over time. If you’re planning for growth or seasonal spikes, ensure the modular equipment you select can scale as needed.

- Can you add more units to meet higher demand?

- Is the system easily reconfigurable for changing workflows?

- Will you be able to integrate new types of equipment without overhauling everything?

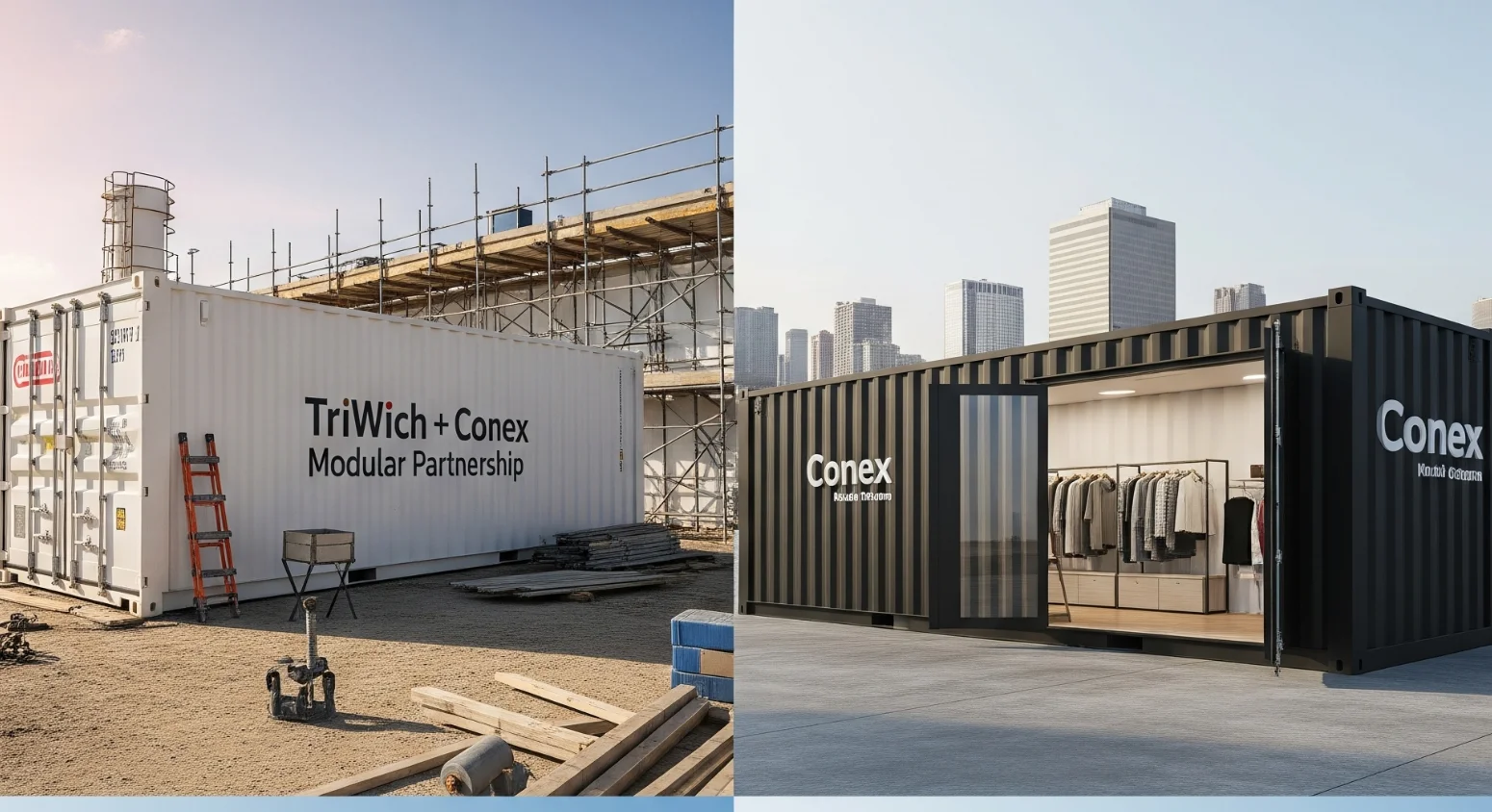

One standout product for this is LiftWich from TriWich. Designed for both tight spaces and heavier loads, it’s fully modular and can adapt to your yard’s needs as they change. Whether you’re adding extra lifting capacity or reworking your yard layout, LiftWich allows for quick adjustments without costly downtime.

3. Prioritize Efficiency and Ease of Use

When you’re considering modular mobility tools, don’t just focus on size and scalability. The ease of use for your team is just as important.

- Are your workers trained to operate the new equipment, or will they need extra time to get up to speed?

- Does the equipment require a lot of manual input, or is it designed for automation?

- How quickly can it be deployed to meet daily demands?

Efficiency doesn’t just mean fast movement; it also means simplifying processes so your workers can focus on what matters most. Look for products like HitchWich, designed to enhance handling efficiency by allowing operators to easily move containers without extra manpower.

4. Consider Long-Term Investment and Maintenance

The goal with any modular solution is to create long-term value, not just a quick fix.

- How much maintenance will the equipment require?

- What’s the expected lifespan?

- Are spare parts readily available, and is the manufacturer reliable?

TriWich products, like the Wheel Dollies, offer excellent durability and easy maintenance, reducing the long-term costs of keeping your equipment in top shape. Investing in high-quality, low-maintenance tools will save you money and prevent delays due to equipment breakdowns.

Best Practices for Implementing Modular Mobility Solutions

So, you’ve chosen the right modular mobility solutions for your freight yard — now what? Implementing these changes doesn’t have to feel like a huge, overwhelming task. With a bit of planning and some smart strategies, you can integrate your new tools without skipping a beat. Let’s talk about the best ways to get things up and running smoothly.

1. Take It Step by Step

It can be tempting to try and roll out everything at once, but trust me — that usually causes more headaches than it solves. Instead, start small and test the waters.

- Pick a few key pieces of equipment that’ll have the biggest impact on your biggest pain points.

- Track how they’re performing, ask your team for feedback, and make any tweaks you need.

- Once you’ve got the first phase working, expand gradually, adding more units as you go.

This approach helps you avoid any big surprises and ensures everything runs like clockwork.

2. Train Your Team Well

New equipment only works as well as the people using it. It’s crucial to give your team the tools and knowledge they need to succeed.

- Make sure everyone knows how to use the equipment safely and effectively.

- Walk them through maintenance procedures and how to integrate the new systems into their everyday routines.

- Offer refresher courses as you add more equipment or make upgrades.

When your team feels confident with the new tools, they’ll work more efficiently, and your freight yard performance will soar.

3. Make Sure Everything Works Together

When adding new modular systems, it’s important that they mesh with what you already have in place. You don’t want to end up with equipment that feels like a puzzle piece that doesn’t quite fit.

- Work with your equipment provider to make sure everything integrates smoothly with your existing systems.

- Use software or tools that let you track everything in real-time and keep operations running seamlessly.

- Keep tweaking and optimizing as you go to make sure everything works in harmony.

The goal is to create a system where everything — old and new — works together effortlessly.

4. Monitor and Adjust

Once your new systems are up and running, don’t just sit back and relax. You’ll need to keep an eye on things to make sure the modular mobility solutions are delivering as expected.

- Track key performance metrics like speed, efficiency, and downtime.

- Use the data to find areas for improvement and adjust as necessary.

- Regularly maintain the equipment to keep everything running smoothly and avoid costly breakdowns.

By staying on top of things, you can fine-tune your system and keep things working at peak performance.

5. Involve Your Team from Day One

The best way to make sure your new equipment sticks is to get everyone on board. Communication is key.

- Let your team know why you’re making the changes and how it’ll benefit them in the long run.

- Ask for their feedback as they start using the new equipment. They’ll have insights you might not think of.

- Celebrate small wins and keep the momentum going!

When everyone is on the same page and feels involved in the process, you’ll get better buy-in and smoother transitions.

Conclusion

Bringing modular mobility solutions into your freight yard isn’t just about upgrading equipment — it’s about transforming the way you work. With the right tools, your operations can run more smoothly, safely, and efficiently. From the flexibility of modular systems to the scalability that helps you grow, these solutions are designed to make your life easier and your yard more productive.

By planning carefully, training your team well, and taking things step by step, you’ll set your yard up for long-term success. The best part? You’ll be ready to tackle whatever challenges come your way in the future, keeping your operations ahead of the curve.

Frequently Asked Questions

1. How long does it take to implement modular mobility solutions?

The timeline really depends on your yard’s size and how much equipment you’re introducing. However, with a phased approach, you can start seeing improvements in just a few weeks, and full integration can usually be completed within a few months.

2. Can modular systems work in smaller yards with limited space?

Yes! Modular solutions are perfect for smaller yards. Tools like LiftWich and HitchWich are specifically designed to help you maximize the use of every square inch, so even tight spaces become efficient and manageable.

3. How do I make sure my team is fully trained on the new equipment?

Training is a key part of success. Make sure your team gets hands-on training that covers both the operation and maintenance of the new equipment. Keep communication open and offer refresher courses to ensure everyone is comfortable and confident as they use the systems.