Ever moved something heavy and felt it shake or jolt with every bump? That’s what happens when there’s no proper shock absorption in heavy load equipment. If you’re working with shipping containers, large machinery, or heavy tools, those shakes aren’t just annoying—they can damage your equipment, mess up your cargo, and even put your team at risk.

So, why does this matter? Every time you lift or move a heavy load—whether it’s with a container jack, a wheel dolly, or a full mobility system—you’re dealing with a lot of weight. Without shock absorption, all that pressure transfers straight into the equipment and whatever you’re moving. Over time, that can cause wear and tear, breakdowns, and expensive repairs.

In this blog, we’re breaking down why shock absorption in heavy load mobility equipment matters more than you might think. We’ll also look at smart tools like container lifting jacks and vehicle wheel dollies that help keep things steady, safe, and working longer. Let’s dive into how better shock control can save you time, money, and a whole lot of hassle.

Table of Contents

I. Understanding Shock Absorption in Heavy Load Mobility

When you’re moving something heavy—whether it’s a shipping container, industrial equipment, or a large piece of machinery—you’re not just lifting weight. You’re managing force, friction, and the hidden stress that comes from sudden stops, uneven ground, or vibrations during movement. That’s where shock absorption in heavy load equipment becomes a game-changer.

What Exactly Is Shock Absorption?

Shock absorption refers to the ability of your mobility equipment to cushion and absorb impact. It minimizes the jarring forces that occur when a load is lifted, transported, or set down.

Think about it this way:

If you’ve ever ridden in a vehicle with poor suspension, every bump feels like a small earthquake. Now imagine that same impact applied to thousands of pounds of cargo. Not ideal, right?

Why Shock Absorption Matters in Heavy Load Mobility

Without proper shock control, the risks go way beyond a rough ride. Here’s what you’re really up against:

- Damage to Cargo: Sensitive or high-value equipment can get damaged from repeated jolts.

- Stress on Equipment: Tools like container lifting jacks and vehicle wheel dollies wear down faster when absorbing too much shock.

- Safety Hazards: Unstable loads increase the risk of tipping, slipping, or unexpected shifts.

- Costly Downtime: Damaged gear or injured team members can bring everything to a standstill.

Where It Happens Most

Shock-related issues tend to show up in places where heavy loads move often and fast:

- Construction zones with rough, uneven terrain

- Warehouses using shipping container dollies or dollies without shock-dampening features

- Loading docks where containers are quickly moved using container jacks

Industries That Can’t Afford to Ignore It

If you’re in one of these sectors, ignoring shock absorption in heavy load equipment could cost you:

- Manufacturing – where sensitive machines need stable relocation

- Logistics and Freight – where containers shift frequently

- Construction – where rough ground meets constant movement

- Military and Defense – where equipment failure is not an option

A Silent Hero in Your Workflow

Most teams don’t notice the role of shock absorption until something breaks. But when it’s built into your equipment—like a well-designed wheel dolly truck or a high-performance container mover—everything runs smoother, safer, and longer.

Shock absorption isn’t just a feature. It’s a form of protection, a performance enhancer, and a long-term investment in your gear and your team.

II. Key Benefits of Shock Absorption in Material Handling

When you’re working with heavy loads, it’s not just about lifting or rolling them from point A to point B—it’s about how they move. Is the motion smooth and controlled? Or does every bump send a jolt through the entire system? That’s where shock absorption in heavy load equipment proves its worth. And the benefits? They’re bigger than you might think.

1. Protects What Matters Most—Your Load

Heavy equipment and containers often carry delicate components or valuable materials. Without proper shock absorption, even a short trip across uneven flooring can cause:

- Cracked components

- Internal damage to machines

- Misalignment of critical systems

Using tools like automotive wheel dollies or a container jack with built-in dampening helps minimize these risks.

2. Reduces Wear and Tear on Equipment

Your tools and machinery are investments. But the more shock and vibration they absorb directly, the faster they wear out. Shock-absorbing systems help:

- Prevent metal fatigue

- Minimize stress on load-bearing parts

- Extend the life of equipment like tire lifts and wheel dolly trucks

That means less downtime and fewer costly repairs.

3. Boosts Safety for Operators

No one wants to be near unstable cargo or an overloaded dolly that jerks unpredictably. Shock absorption plays a direct role in:

- Keeping loads balanced

- Preventing slips, drops, or sudden shifts

- Creating smoother handling conditions for operators

This becomes even more important when using container movers in tight or fast-paced environments.

4. Improves Efficiency and Speed

With fewer bumps and less resistance, shock-absorbing tools allow operators to move loads more confidently and quickly. That translates to:

- Faster job completion

- Reduced fatigue for staff

- Smoother transitions between stages of work

You’re not just moving things—you’re doing it smarter.

5. Cuts Long-Term Costs

Sure, shock-absorbing equipment might have a higher upfront cost. But the long-term savings in:

- Equipment maintenance

- Damaged goods

- Labor efficiency

- Injury prevention

…make it one of the smartest choices in heavy load mobility.

III. How LiftWich Enhances Shock Absorption in Motion

Built for Smooth, Safe Lifting

Moving heavy equipment isn’t just about lifting—it’s about doing it safely and without damage. That’s where LiftWich comes in. It’s specially designed to make sure every lift is balanced and stable. In situations where shock absorption in heavy load matters most, LiftWich keeps everything steady and under control.

Key Benefits of LiftWich’s Design:

- Spreads weight evenly to prevent tilting or sudden shifts

- Built-in features that reduce shaking and jolting during lifts

- Helps protect both your cargo and your lifting gear

Works Seamlessly with Wheel Dollies

LiftWich becomes even more powerful when paired with tools like wheel dolly trucks or auto dolly wheels. This combo helps manage shock from both the ground and the lift itself.

What This Combo Does Well:

- Absorbs floor-level bumps through the dolly

- Reduces impact on the cargo during movement

- Creates smoother transport, even across rough surfaces

Designed for Tough Environments

LiftWich is made to perform in real-world places like construction sites, warehouses, and shipping yards—where bumps, slopes, and fast-paced work are common. When used alongside shipping container dollies or a container jack, LiftWich brings control to even the most unpredictable moves.

Why It Matters in the Field:

- Helps avoid sudden drops or slips

- Keeps loads stable in tight or uneven spaces

- Reduces strain on workers during lifting and moving

Protects Your Investment

Every time LiftWich absorbs shock instead of letting it hit your gear or your team, you’re saving money and lowering risks.

Long-Term Benefits Include:

- Fewer repairs to lifting equipment

- Less damage to cargo during transport

- Safer working conditions for your team

If your current setup makes every lift feel risky or rough, it might be time for an upgrade. LiftWich delivers reliable shock absorption in heavy load moves, helping you work smarter, safer, and more efficiently—every single time.

Also Read: How to Move Multiple Containers Without Heavy Machinery

IV. Common Challenges in Heavy Load Movement—and How Shock Absorption Solves Them

If you’ve ever struggled to move a heavy container or machine, you’re not alone. Whether it’s rolling a load across uneven ground or lowering it without a sudden drop, heavy-duty mobility comes with its fair share of challenges. But here’s the good news: many of these problems can be solved—or at least seriously reduced—by improving shock absorption in heavy load handling.

Let’s take a closer look at the everyday issues teams face and how the right shock-absorbing equipment, like container movers and vehicle wheel dollies, can make all the difference.

1. Bumpy or Uneven Surfaces

Not every job site has smooth, flat flooring. Construction zones, outdoor yards, and even older warehouses can create serious vibration and impact when moving loads.

Shock Absorption Helps By:

- Cushioning the load as it rolls over cracks, dips, or gravel

- Reducing stress on wheel dolly trucks and their frames

- Keeping cargo stable even when the path isn’t

2. Sudden Shifts and Tipping Risks

A quick turn or stop can make a load shift sharply, sometimes dangerously. Without shock control, that momentum can throw everything off balance.

With Better Shock Absorption, You Can:

- Maintain steadier movement with less sway

- Reduce tipping risk when navigating corners or tight areas

- Improve control during starts, stops, and turns

3. Excessive Wear on Equipment

When your gear takes all the hits, it wears out fast. Over time, that means more downtime and higher maintenance costs.

Shock-Reducing Tools Like:

- Container lifting jacks

- Tire lifts

- And auto dolly wheels

… help absorb repeated impact and vibration, protecting your tools from long-term damage.

4. Cargo Damage During Transport

Even if a container looks solid on the outside, what’s inside might be sensitive. Electronics, machinery, or parts can easily be damaged by the shock of rough handling.

Shock Absorption in Heavy Load Equipment Helps You:

- Move delicate items more safely

- Prevent bouncing or rattling during transport

- Avoid costly damage claims or delays in operations

5. Operator Fatigue and Injury Risk

Let’s not forget the people doing the work. Constant vibrations, jarring motions, and awkward equipment handling can wear down your crew quickly—and lead to injury over time.

The Right Equipment Helps By:

- Making loads feel lighter and more stable

- Reducing the effort needed to control movement

- Creating a safer, more comfortable working experience

By understanding these common challenges, it’s easier to see how important shock absorption in heavy load really is. It’s not just a nice-to-have—it’s a key factor in safer, smoother, and more cost-effective load handling. And with smart tools like container movers and vehicle wheel dollies, you’re not just moving heavy stuff—you’re doing it the right way.

Explore: Automated Guided Vehicles vs Traditional Dollies

V. Why Shock Absorption Should Be a Priority in Your Heavy Load Equipment

Have you ever thought about what takes the biggest hit during heavy load movement? It’s not just the equipment—it’s the wear and tear on your cargo, your team, and your workflow. That’s why shock absorption in heavy load gear shouldn’t be an afterthought. It should be one of the first things you look for.

The smoother the ride, the better the outcome. But that only happens when you’re using the right tools—ones designed to absorb impact, reduce bounce, and create a stable moving experience from start to finish.

1. It Protects More Than Just the Load

Sure, shock absorption keeps your cargo safer. But it also protects:

- The flooring in your facility

- Your lifting and moving equipment

- The health of your operators

Using equipment like container lifting jacks and auto dolly wheels helps limit harsh impact, reducing long-term strain on everything involved in the move.

2. It Improves Performance and Confidence

When you or your team know that loads won’t jolt or slip unexpectedly, it becomes easier to move faster without sacrificing safety. Better shock absorption means:

- Smoother motion across all surfaces

- Less hesitation during tight turns or narrow paths

- More efficient workflows from loading to unloading

With tools like vehicle wheel dollies, even heavy containers feel more manageable.

3. It Extends Equipment Lifespan

Constant shock wears down even the toughest gear. But when your setup includes shock-dampening features, you give your equipment a longer life. For example:

- A container jack with solid suspension absorbs stress at the source

- Shipping container dollies with padded wheels reduce friction and resistance

These details add up over time—saving you money on repairs and replacements.

4. It Cuts Down on Unexpected Costs

Every time a load is dropped, a wheel cracks, or something breaks, it costs you. Not just in materials, but in time, safety, and trust.

Prioritizing shock absorption in heavy load handling helps:

- Prevent avoidable damage

- Lower the risk of operator injury

- Reduce downtime from equipment failure

5. It Reflects a Smarter, Safer Operation

At the end of the day, investing in better shock absorption isn’t just good practice—it shows that your operation values quality, safety, and forward thinking.

When your equipment is built to move smart, you build trust with your team, your clients, and your results.

So ask yourself: Is your current setup doing enough to absorb the real weight of your work? If not, it may be time to upgrade to tools that take shock seriously—and help you move more confidently, every step of the way.

Know More: The Benefits of Removable Shipping Container Wheels

Conclusion: Make Shock Absorption Your Competitive Advantage

When it comes to moving heavy loads, you’re not just shifting weight—you’re managing risk, protecting your equipment, and keeping your operations running smoothly. And as we’ve seen, shock absorption in heavy load movement isn’t just helpful—it’s essential.

The real question is: Are you relying on outdated tools that cause more harm than good? Or are you ready to invest in smarter, safer, more efficient solutions?

From smoother motion and less equipment wear to better operator safety, shock-absorbing tools like container lifting jacks, shipping container dollies, and vehicle wheel dollies offer real, measurable value. They don’t just improve how you move loads—they change how you work.

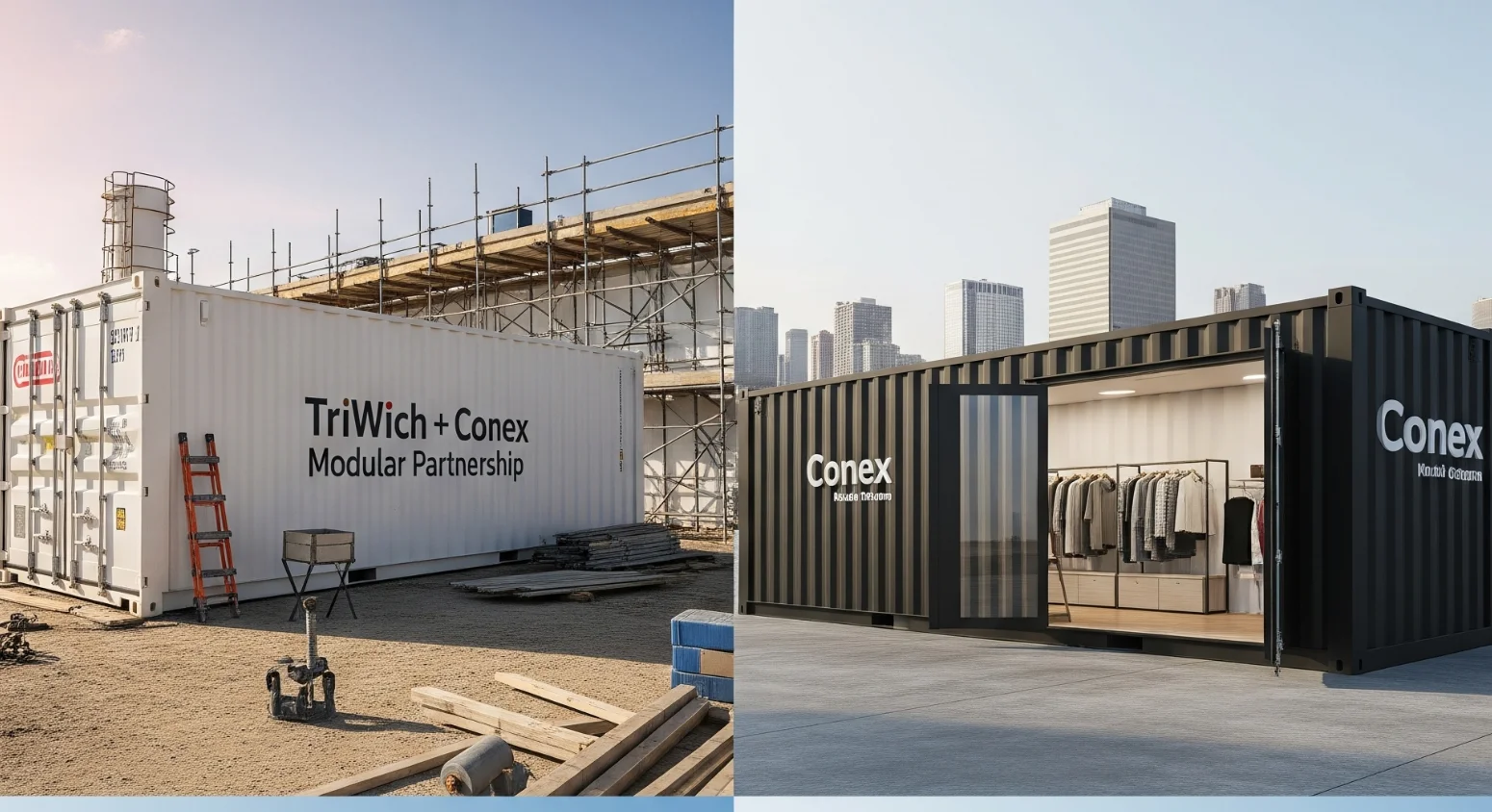

At TriWich, we understand that success in heavy-duty mobility is built on performance and precision. That’s why we’ve designed solutions like LiftWich to bring the shock absorption you need, without overcomplicating your workflow.

So the next time you face a demanding load move, ask yourself this: Is your equipment absorbing the shock—or is your team and cargo paying the price?

Frequently Asked Questions

1. Why is shock absorption important in heavy load movement?

Shock absorption helps prevent damage to your cargo, reduces stress on your equipment, and improves safety for your team. It ensures smoother, more controlled movement across all surfaces.

2. What equipment offers good shock absorption for heavy loads?

Tools like container jacks, shipping container dollies, and vehicle wheel dollies are designed to handle heavy loads while minimizing impact, vibration, and strain.

3. Can shock-absorbing equipment extend the life of my tools?

Absolutely. Reducing repeated shock and vibration helps protect your lifting gear, wheels, and frames from wear and tear—saving you money on repairs and replacements.

4. Is shock absorption only useful on rough terrain?

Not at all. Even smooth warehouse floors can cause damaging vibration during movement. Shock absorption is valuable wherever heavy loads are lifted or rolled, especially in high-traffic or high-pressure environments.