Have you ever seen those big metal boxes on trucks, ships, or at construction sites and wondered what they are? Those are called Conex containers, and they play a huge role in how things are stored, shipped, and even built today.

But what is a Conex container, really? Why do so many industries rely on them? Whether you’re working in shipping, building something on-site, or just curious about how storage works, learning about Conex containers can be really helpful.

In this blog, we’ll explain what a Conex container is, where it came from, and how it’s used today. You’ll see why it’s more than just a big metal box—it’s a smart, strong, and useful tool for many jobs.

Let’s get started and take a closer look at this simple but powerful container.

Table of Contents

1. Origins and Evolution of the Conex Container

Have you ever wondered how global shipping became so fast, organized, and efficient? It all started with a simple idea: pack cargo into a strong, reusable metal box that could move smoothly between trucks, ships, and trains. That idea led to the creation of the Conex container, and it changed the way the world moves goods.

A Wartime Solution That Sparked a Global Shift

The Conex container was first introduced by the U.S. military during the Korean War. Back then, transporting supplies was messy, slow, and unreliable. The military needed a better way to move equipment and goods—something sturdy, secure, and reusable. Their solution? The “Container Express,” shortened to Conex.

These early boxes were:

- Steel-built to handle rough conditions and long hauls

- Stackable and weatherproof, ideal for military use

- Lockable and efficient, making cargo theft less likely

It didn’t take long for other industries to see how useful they could be.

From Military Tool to Global Trade Standard

After the war, the benefits of containerization caught the attention of the commercial shipping industry. In the late 1950s, Conex-style containers were adapted for international use—and the shipping world hasn’t looked back since.

Why was this such a big deal?

- Faster loading and unloading meant quicker deliveries

- Standard sizes helped streamline transport across ships, trains, and trucks

- Lower costs for businesses, thanks to reusable and reliable storage

These boxes didn’t just change how things were moved—they reshaped entire supply chains across the globe.

Why It Still Matters Today

When someone asks, “What is a Conex container?”—they’re really asking about one of the most important innovations in modern logistics. These containers made trade faster, safer, and more scalable. And even after decades of use, their impact continues.

In fact, companies today are still building on that legacy.

2. Defining Features of a Conex Container

So, what actually makes a Conex container so reliable, and why is it trusted around the world for everything from shipping cargo to setting up pop-up offices? Let’s break it down. Understanding the build and features of these containers gives you a clearer picture of why they’re still a go-to choice in so many industries.

Built to Last: Materials That Make a Difference

At the core of every Conex container is strength. These containers are built using heavy-duty, corrosion-resistant steel, designed to handle rough weather, long-distance transport, and container heavy stacking.

Key structural elements include:

- Corten steel walls and frame – rust-resistant and highly durable

- Marine-grade plywood or steel flooring – strong enough for forklifts

- Reinforced corner castings – allow for secure stacking and lifting

This rugged construction is what makes them ideal for long-term outdoor use—whether on a construction site or at sea.

Standardized for Global Use

No matter where a Conex container is used, it follows international size standards. This is crucial because it allows them to fit seamlessly on ships, trains, and trucks without modification.

The two most common sizes are:

- 20-foot container (also known as a TEU – Twenty-foot Equivalent Unit)

- 40-foot container – for larger or bulkier loads

Both sizes are 8 feet wide and 8.5 feet high (standard), though you can also find High Cube models that add an extra foot of vertical space for taller cargo.

Safe, Secure, and Easy to Handle

One of the reasons so many businesses turn to Conex containers is their security. They’re designed with protection in mind—keeping goods safe from theft, water, and pests.

Common features include:

- Double doors with locking bars for tight, tamper-proof sealing

- Weatherproof gaskets to block out moisture

- Forklift pockets and corner fittings for quick and safe movement

All of this adds up to fewer damaged goods, lower insurance claims, and peace of mind when storing or transporting valuable materials.

Why This Matters to You

If you’re in logistics, construction, or even retail, knowing these details helps you make smarter decisions. You’ll know what to expect in terms of durability, what kind of loads it can handle, and how easily it can be moved or modified.

So the next time someone asks you to define a Conex container, you’ll know it’s not just a steel box—it’s a well-designed tool built for performance, security, and global compatibility.

Stay with us as we dive into the many types of Conex containers available and how each one serves a different purpose.

3. Types of Conex Containers and Their Uses

Not all Conex containers are built the same—and that’s a good thing. Depending on what you need to store, ship, or build, there’s likely a container designed to fit that exact purpose. So if you’ve ever thought, “Can one box really do it all?”, the answer is: not quite—but there are several types that together cover almost every need.

Let’s explore the most common types and what makes each one useful.

1. Standard Dry Storage Containers

These are the classic Conex containers most people picture: sealed, secure, and ready for anything.

Ideal for:

- Storing equipment or tools

- Transporting boxed or palletized goods

- Serving as temporary on-site storage

Available sizes:

- 20-foot

- 40-foot

This is the go-to option for most general storage and shipping needs.

2. High Cube Containers

Need more vertical space? High cube containers are just like standard ones—but taller by one foot (9.5 ft instead of 8.5 ft). That extra space can make a big difference, especially for bulky or irregularly shaped items.

Great for:

- Oversized equipment

- Lightweight, high-volume goods

- Modular building conversions (e.g., pop-up offices)

3. Open-Top Conex Containers

These containers feature a removable roof—usually made of tarpaulin—allowing for easy loading of cargo that’s too tall or awkward for regular doors.

Best suited for:

- Machinery

- Pipes and construction materials

- Top-loaded cargo with cranes or forklifts

They’re all about flexibility when side or door access isn’t enough.

4. Flat Rack Containers

Flat racks are essentially Conex containers without walls or a roof. They have strong end walls that support heavy loads, and they’re perfect when you’re working with unusually shaped cargo.

Perfect for:

- Vehicles or equipment on wheels

- Industrial parts

- Long pipes or beams

You can load from the top or sides, making these incredibly versatile for complex transport jobs.

5. Modified or Custom Containers

Here’s where things get exciting. Modified Conex containers take the standard box and transform it. From mobile offices to refrigerated units, these containers prove just how flexible a steel box can be.

Common modifications include:

- Windows, HVAC, and electrical wiring

- Roll-up doors or extra entry points

- Insulation for cold or hot climates

These are great if you’re building out a workspace, retail unit, or even a home office.

Which Conex Container Is Right for You?

Choosing the right container depends on what you’re trying to solve. Do you need height? Go for a high cube. Working with awkward shapes? Try an open-top or flat rack. Need something beyond storage? Consider a modified container.

So, when someone asks you to explain a Conex container, you now know—it’s not just one thing. It’s a category full of solutions designed for real-world challenges across industries.

Stay tuned as we explore real-life Conex container examples that show just how flexible and powerful these units can be in action.

Know More: The Best Container Lifting Jacks for Uneven Terrain

4. Common Applications Beyond Shipping

When you hear the term Conex container, your mind might immediately jump to cargo ships and ports. But have you ever stopped to think about just how many different ways these steel boxes are used beyond shipping? The truth is, Conex containers are much more than transport vessels—they’re versatile tools that serve countless industries and creative projects.

Let’s explore some surprising and practical Conex container examples to inspire how you might use one too.

1. Construction and Job Site Storage

On construction sites, keeping tools, materials, and equipment safe and organized is a constant challenge. That’s where Conex containers shine.

- They provide secure, weatherproof storage for everything from power tools to bulk materials.

- Their stackability and mobility mean you can move your storage as the project evolves.

- They also double as temporary offices or break rooms when modified.

2. Mobile Offices and Workspaces

Have you noticed pop-up offices or workspaces on-site or in remote areas? Many of those are modified Conex containers.

- Insulated and fitted with windows, lighting, and climate control

- Durable enough to withstand harsh outdoor conditions

- Easy to transport and set up anywhere

This flexibility makes them a favorite for remote work sites, event management, and even emergency response centers.

3. Retail and Pop-Up Shops

In urban areas, businesses are turning to Conex containers to create temporary or permanent retail spaces.

- They’re affordable compared to traditional builds

- Customizable with doors, windows, and branding

- Quick to deploy in high-foot-traffic areas

This approach is popular for food stalls, boutique shops, and art galleries.

4. Storage for Agriculture and Farming

Farmers and agricultural businesses use Conex containers to store equipment, seeds, and chemicals safely.

- Protect sensitive items from the elements

- Keep tools secure from theft

- Easily relocate storage based on seasonal needs

5. Emergency and Disaster Relief

In disaster zones, speed and durability matter most. Conex containers provide quick, robust shelters or storage units for supplies.

- Weatherproof and secure

- Can be stacked or grouped for larger facilities

- Easily transported to remote or damaged areas

Why Consider a Conex Container for Your Needs?

No matter your industry, the adaptability of these containers makes them worth considering. From simple storage to fully customized spaces, Conex containers bring a durable, cost-effective, and mobile solution to many challenges.

If you’re curious about how these containers might fit into your next project, keep reading. We’ll share the key benefits of using Conex containers and how they can help you save time, money, and headaches.

Explore: Choosing the Right Shipping Container Jack

5. Real-Life Examples: How Conex Containers Help in Everyday Use

It’s one thing to talk about Conex containers, but it’s even better to see how they work in real life. Have you ever wondered how these steel boxes help different businesses and people? Let’s look at some easy-to-understand examples of Conex container uses.

Example 1: Making Construction Work Easier

A construction company needed a safe place to keep tools and materials at different job sites. They tried regular storage options, but those were expensive and hard to move.

With Conex containers, they got:

- Strong, weatherproof storage that locked up tight

- Storage units that could be moved easily when needed

- Less theft and damage, saving money and time

This helped them keep their work on track without worrying about lost tools.

Example 2: A Quick and Easy Pop-Up Shop

A small business wanted to open a store without paying a lot for rent or building costs. They used a modified Conex container as a pop-up shop because:

- It could be set up fast in busy areas

- They could add windows, doors, and their logo

- They could move it to different spots depending on where customers were

This helped them reach more people without spending too much money.

Example 3: Helping in Emergencies

In emergencies like natural disasters, getting help quickly is very important. Groups use Conex containers as mobile clinics or to store supplies because:

- They can be moved easily to where they’re needed

- They keep important medical equipment safe

- They can be stacked or connected to make bigger spaces fast

These containers help people get help faster when it matters most.

What You Can Take Away

These examples show that Conex containers aren’t just boxes—they are flexible tools that save money, time, and effort.

If you’re thinking about using a Conex container for your business or project, remember they can be storage, offices, shops, or more.

Want to learn how to choose and take care of the right container? Keep reading for our simple tips to get the best from your Conex container.

Also Read: Top Container Handling Equipment for All-Scale Operations

Conclusion

To wrap things up, have you noticed how much a simple Conex container can really do? They started out as strong shipping boxes but have grown into so much more—secure storage, mobile offices, pop-up shops, and even emergency shelters. When you understand what a Conex container is and how it works, you see just how useful and flexible these steel boxes really are.

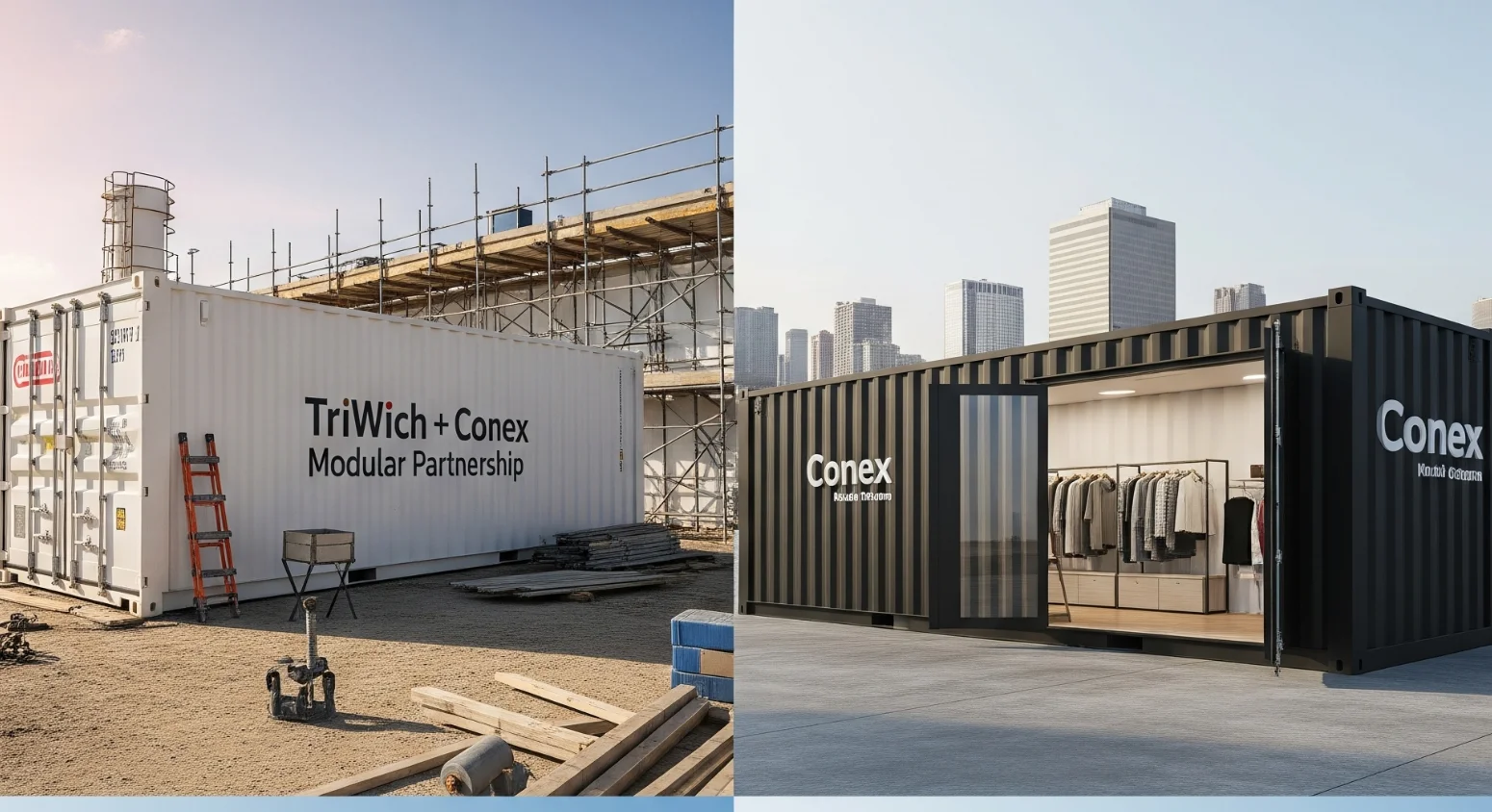

Working with trusted partners like TriWich and Conex Modular means you’re not just buying a container—you’re getting a smart solution that helps your projects run smoothly and saves you time and hassle.

Curious about how a Conex container could work for you? Take the next step, ask questions, and explore the many ways these containers can make your life easier and your business better.

Frequently Asked Questions

Q1: What else can I use a Conex container for besides shipping?

You can use Conex containers for secure storage, offices, retail spaces, or even as shelters during emergencies. They’re very versatile.

Q2: Are Conex containers strong enough to last?

Yes, they’re made from tough steel that can handle bad weather and rough use, so they last a long time.

Q3: Can I change a Conex container to fit my needs?

Absolutely! You can add windows, doors, insulation, and more to make it fit exactly what you need.

Q4: How do I pick the right Conex container?

Think about what size and type you need, like a regular, tall (high cube), or open-top container. Working with experts like TriWich can help you find the perfect one.